Comparison of Gas Installation by:

An EMA-Licensed Gas Service Worker vs. a Non-Licensed Handyman

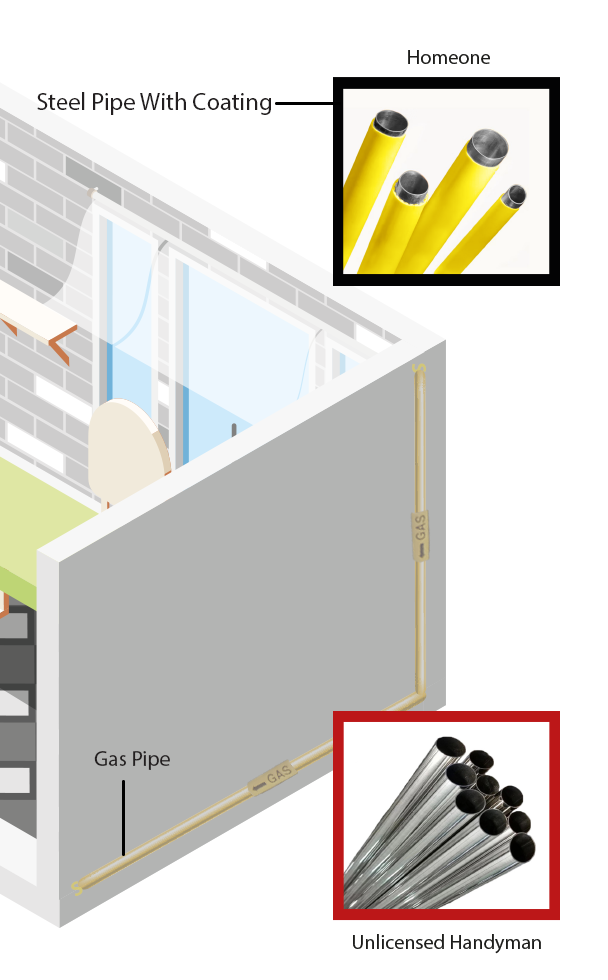

Above False Ceilings

EMA-Licensed Gas Service Worker

False Ceilings: Except for welded steel pipes, galvanised iron and copper pipes must not have joints.

Non-Licensed Handyman

Compression Joints in False Ceilings: Uses unreliable compression fittings for copper pipes in concealed spaces, increasing the risk of undetected leaks.

Bedrooms

Bedrooms: Gas pipes must not be routed through bedrooms.

Routing Through Bedrooms: Incorrectly routes gas pipes through bedrooms, violating safety regulations.

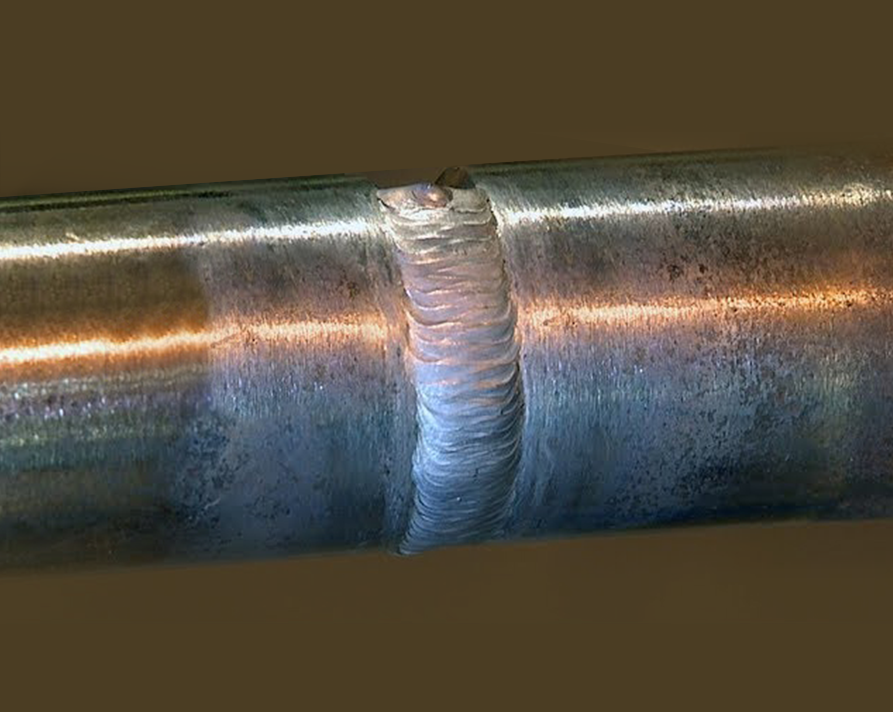

External/Cavity Walls

External/Cavity Walls: Uses protective sleeving and corrosion-resistant coatings for pipes chased into porous or external walls (SS 608 Clause 6.3).

Cavity Wall Risks: Installs pipes without appropriate sleeving or corrosion protection, leading to long-term degradation.

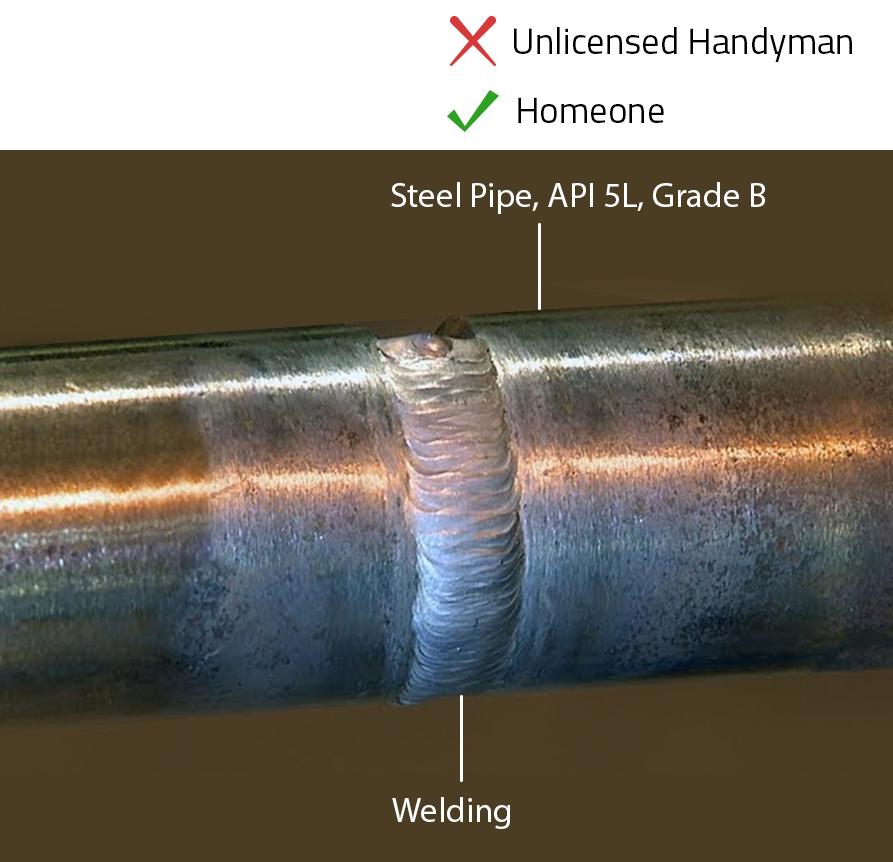

Steel Pipes (API) and Radiographic Inspection

(SS 608 Clause 6.7)

- Uses API 5L Grade B steel pipes for durability and pressure resistance.

- Welds steel pipes as required by SS 608 Clause 6.7(b).

- Uses non-compliant pipes, which may be of inferior quality and prone to rupture.

- Skips welding, opting for cheaper threaded joints, violating SS 608 requirements.

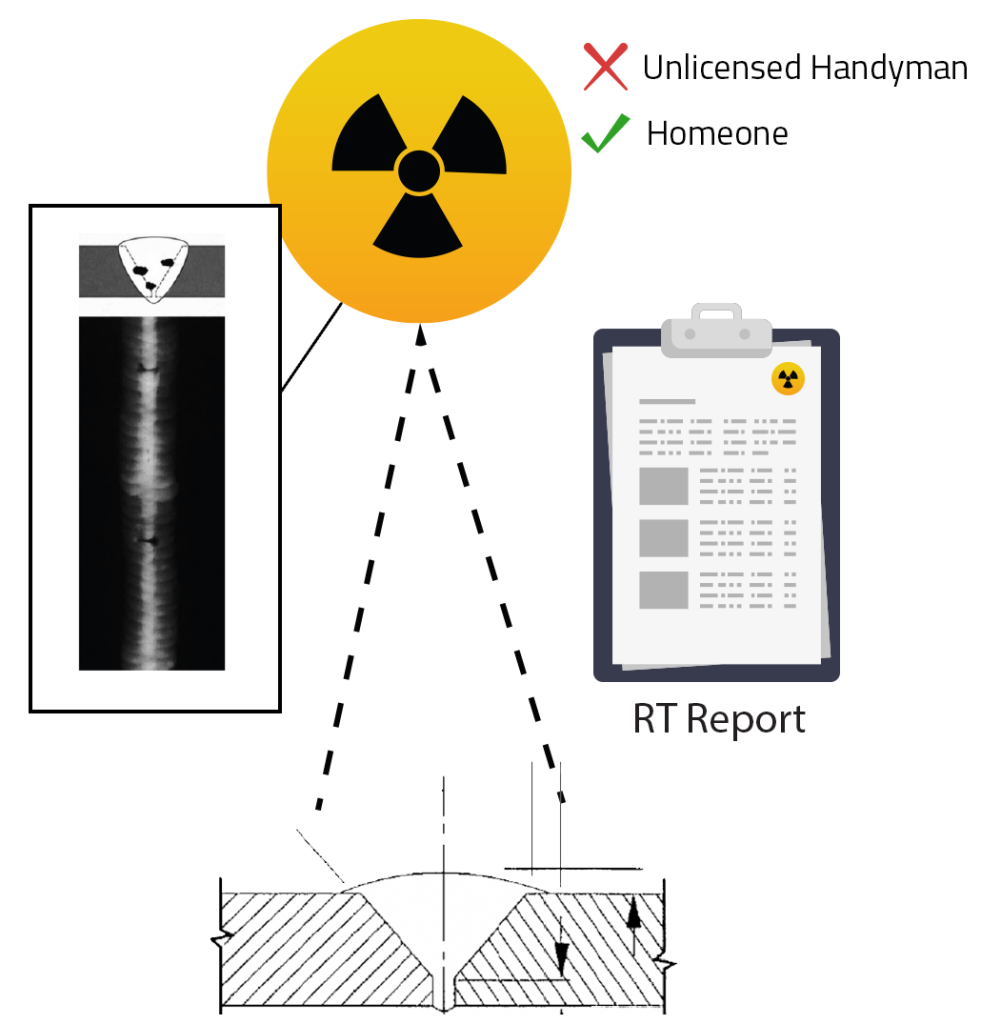

Radiographic Testing

- Conducts radiographic testing (RT) in accordance with API 1104 to detect weld defects.

- Maintains RT reports for regulatory inspections by the Energy Market Authority (EMA).

- No radiographic inspection, leaving potential weld defects undetected.

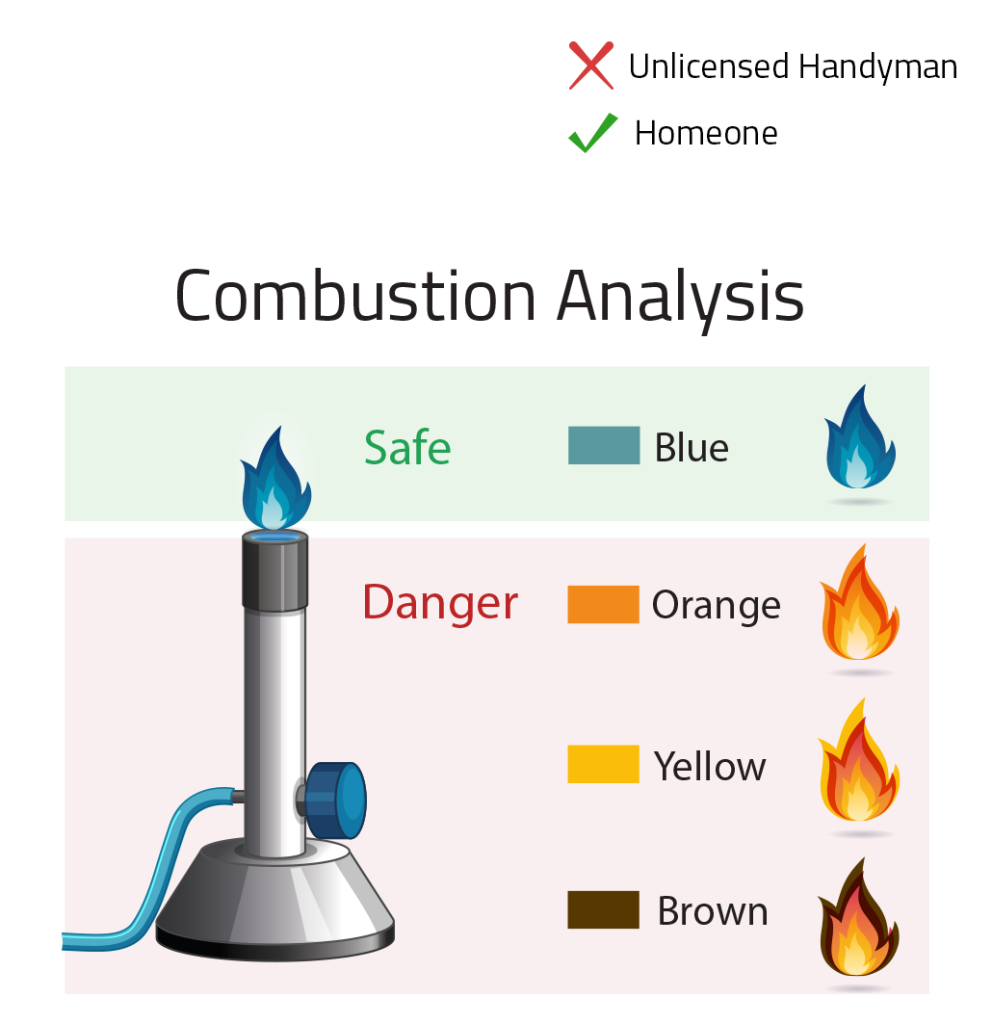

Gas Appliance Commissioning

(SS 608 & Gas Regulations)

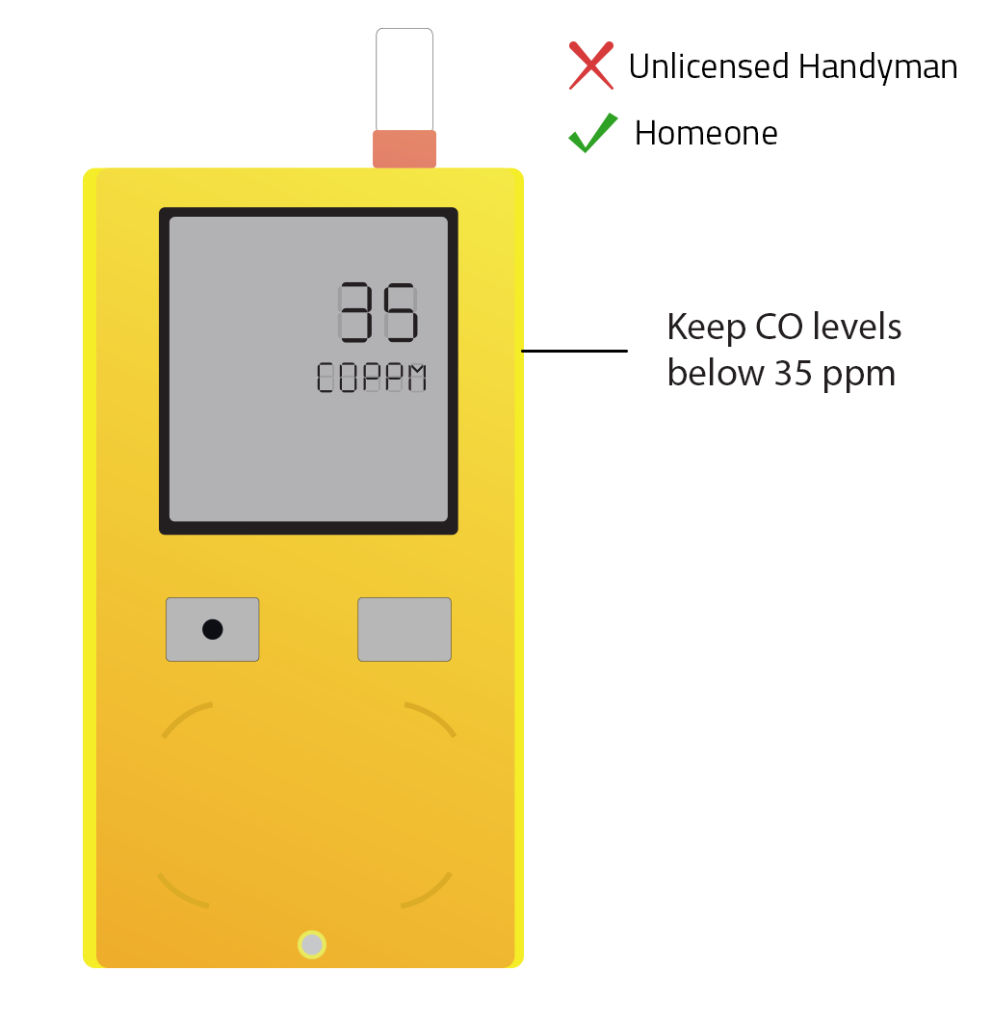

Minimal CO-Emission

- Ensures gas-air ratios (e.g., 10:1 for boilers) are correct for complete combustion and minimal CO emissions.

- No combustion analysis, increasing the risk of CO poisoning due to incomplete combustion.

- Verifies flue functionality to keep CO levels below 35 ppm.

- Ensures adequate ventilation in accordance with Regulation 20(d).

- No certification, meaning appliances are illegally installed (Regulation 21(3)).

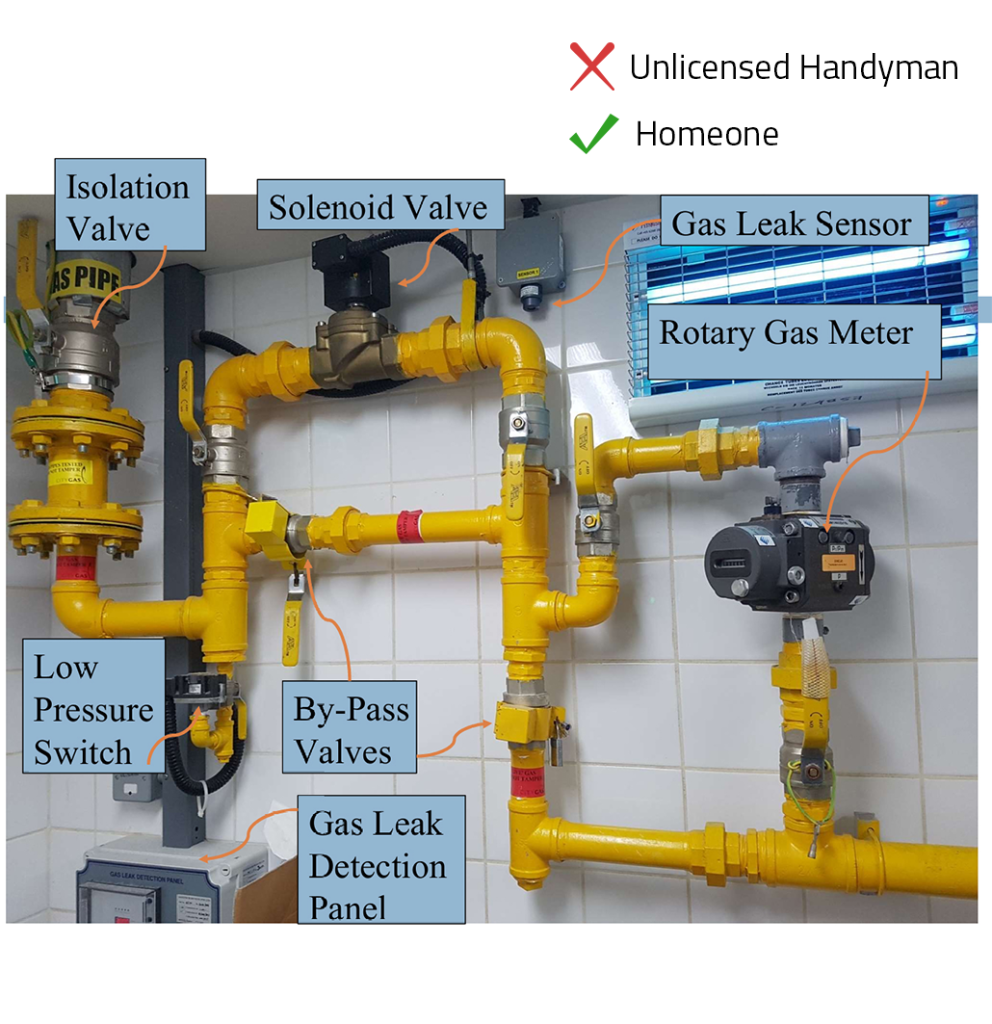

Automatic Cut-off Systems

Interlocking Safety Systems

- Installs automatic cut-off systems that shut off the gas supply if ventilation fails.

- Fails to install interlocking safety systems, leaving gas appliances unprotected.

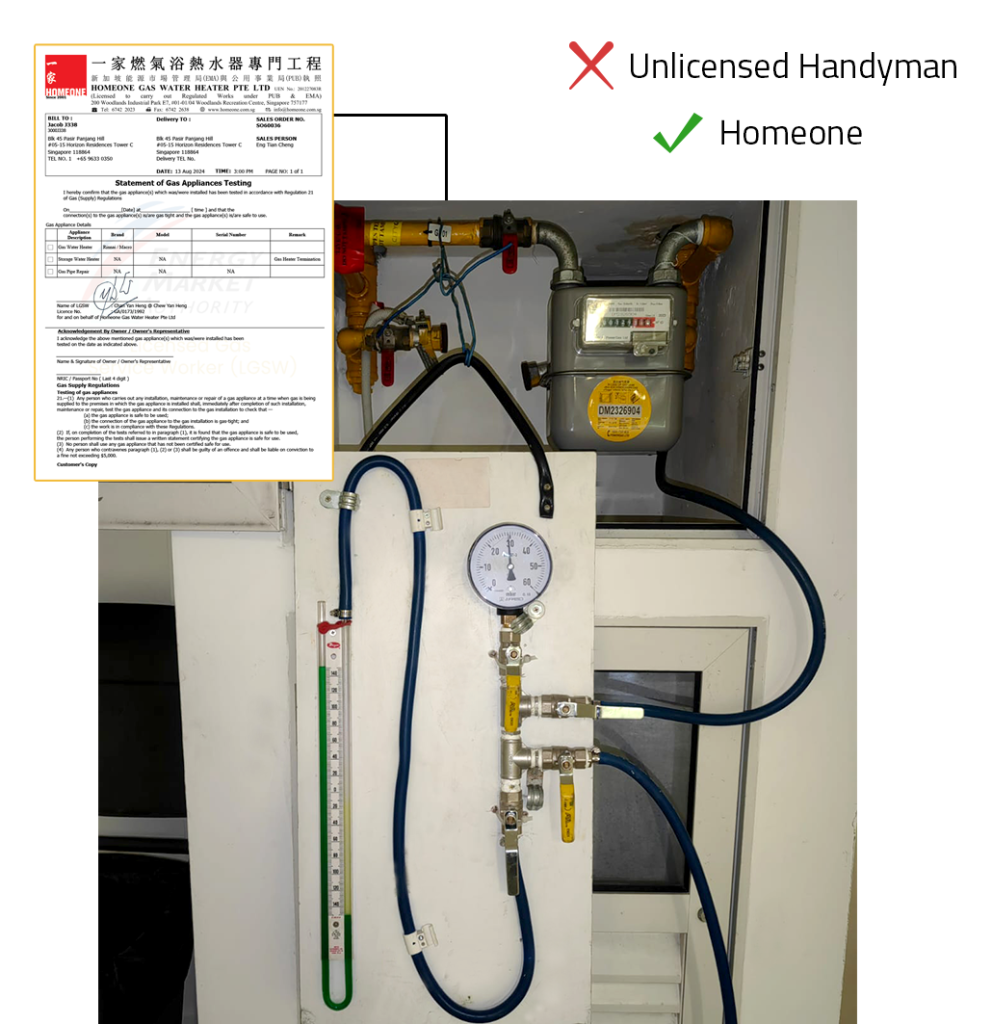

Gas Pipe Testing and Inspection

(SS 608 Clause 8)

- Conducts two-stage pressure testing (140 kPa for 24 hours on polyethylene pipes).

- Uses a 300 mm water U-gauge for 5 minutes for internal pipes.

- Performs gas-tightness tests under live conditions (Regulation 21(1)).

- Uses soap testing on joints to detect micro-leaks.

- Skips pressure testing, increasing the likelihood of undetected leaks.

- Relies on visual checks rather than using U-gauge or soap tests

| Aspect | EMA-Licensed Gas Service Worker | Non-Licensed Handyman |

|---|---|---|

| Pipe Routing | No gas pipes in bedrooms; uses sleeving in cavity walls. | Routes pipes through bedrooms; no corrosion protection. |

| Steel Pipe Welding | API 5L Grade B + API 1104 radiographic inspection. | Uses low-grade steel; skips weld testing. |

| Jointing in Concealed Areas | Uses brazed or soldered joints in false ceilings. | Uses compression fittings, increasing leak risk. |

| Appliance Commissioning | Conducts gas leak tests, CO checks, and safety interlocks. | No leak testing; appliances left uncertified. |

| Final Testing | Two-stage pressure tests + radiography for welds. | Incomplete testing; relies on visual inspection. |

Conclusion

An EMA-licensed gas worker ensures compliance with SS 608 and Gas Regulations by:

- Avoiding concealed compression joints.

- Using radiographic testing (RT) for welded steel pipes.

- Conducting combustion testing and appliance commissioning.

In contrast, a non-licensed handyman risks:

- $5,000 fines per violation (Regulation 21).

- Carbon monoxide poisoning risks due to incorrect combustion.

- Explosion hazards from undetected gas leaks in ceilings.

For example, a handyman installing compression joints in a false ceiling could cause an undetected gas leak, accumulating until an explosion occurs. Always engage a licensed professional to ensure compliance, safety, and peace of mind.